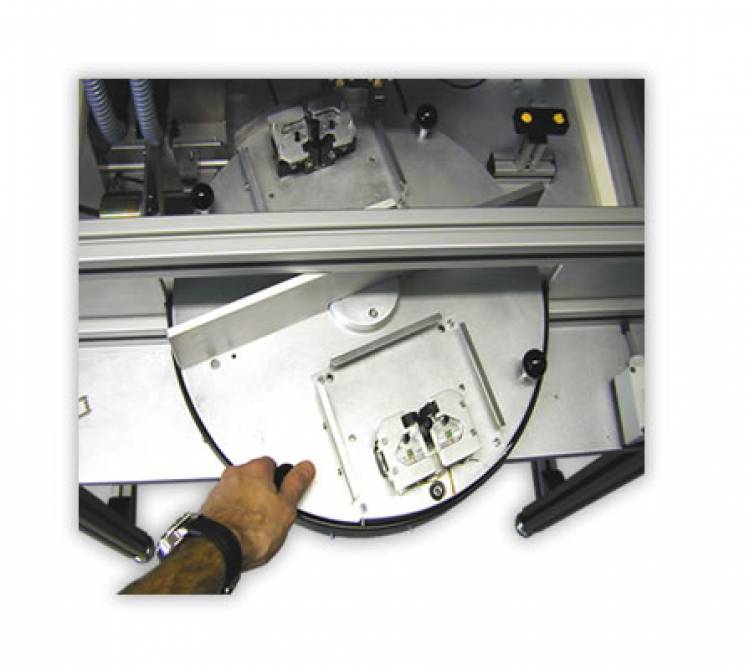

Double Hot Bar Soldering System with rotary table

Stand-alone edition.

Diameter of turntable: 500mm

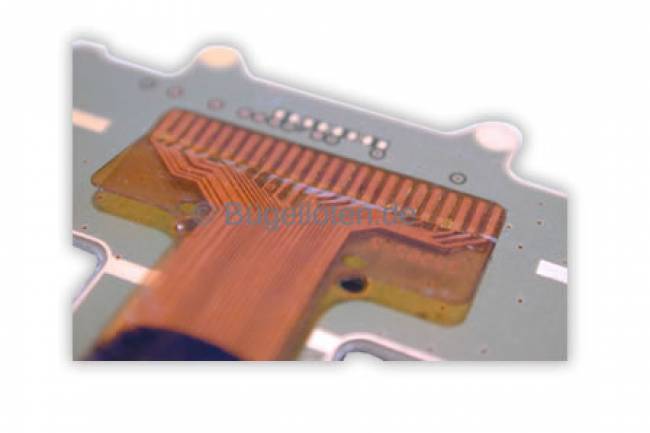

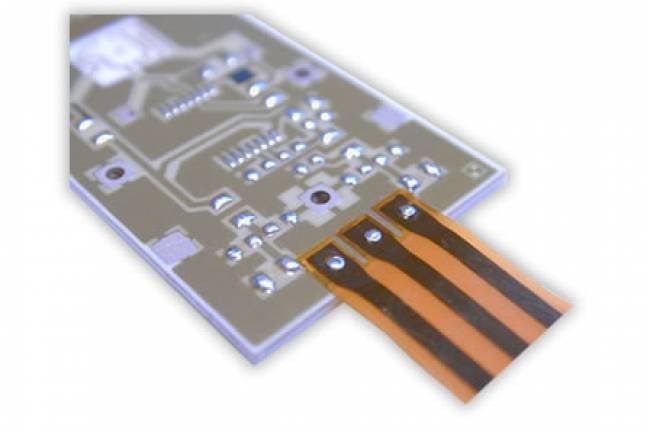

Soldering system for soldering stranded wires with two separately working soldering bars.

On each jig there are two products that can be soldered simultaneously.

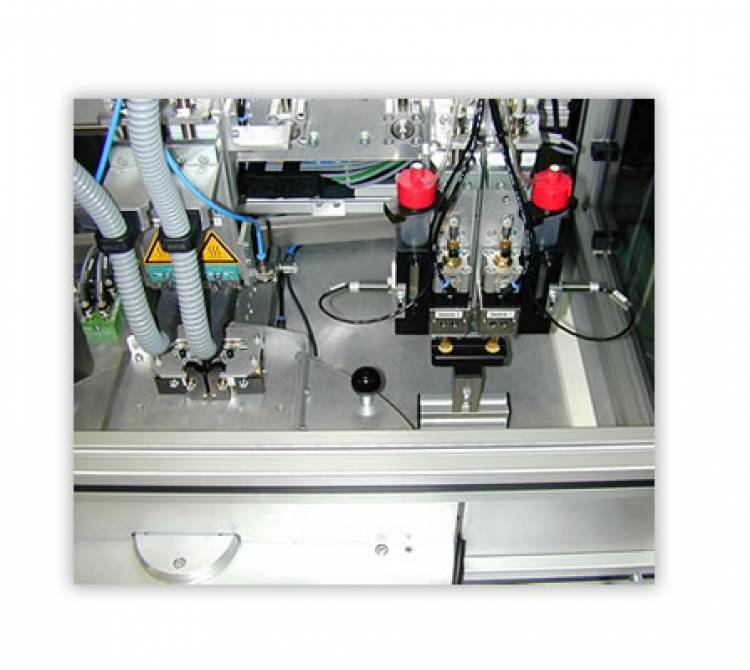

After manual turning the table, flux is applied onto the joint components (soldering area and stranded wires) with a profiled dispensing nozzle (MV2000 dispensing valve).

Both the flux unit and the soldering unit are fixed to an x-axis. The units are moved above the jig as required.

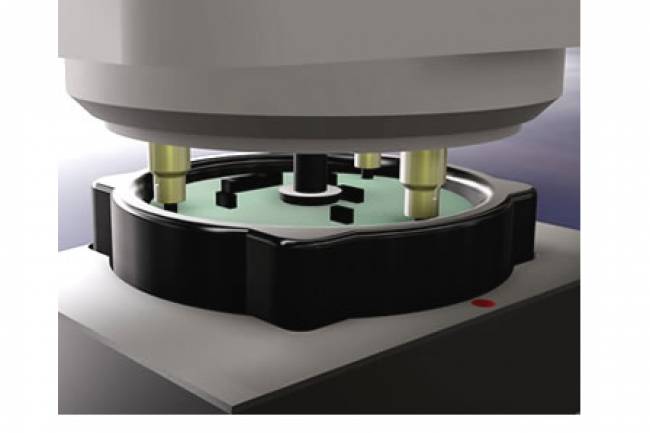

After the flux process the hot bar soldering process takes place.

The system is equipped with an automatic cleaning station for the soldering bar.

The cleaning process takes place during the flux application and, therefore, does not affect the cycle time.