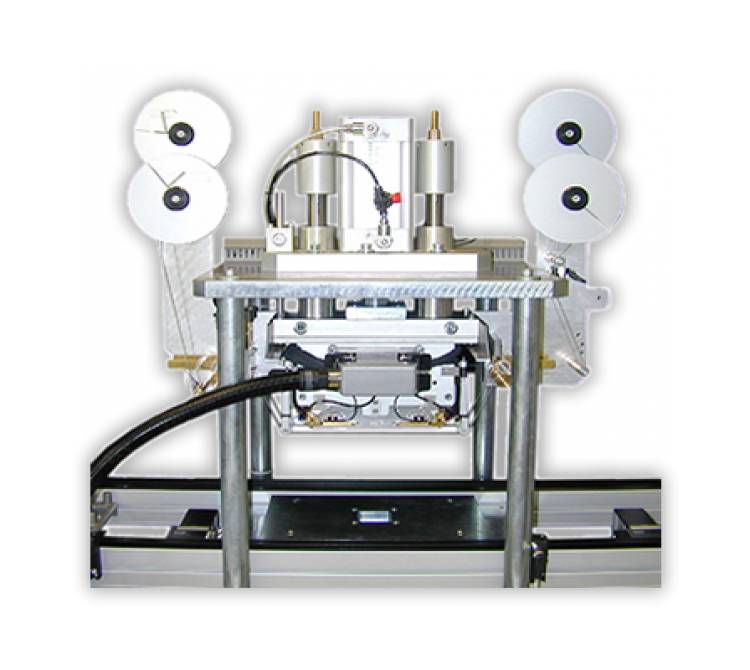

In-line Heat sealing system with an integrated Bosch transfer belt

In-line Heat sealing system with an integrated Bosch transfer belt.

The system is for integration into a customers existing production line or into a planned line.

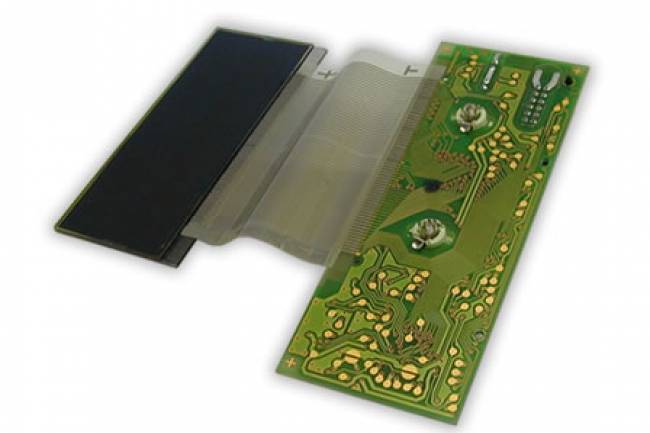

Incoming workpieces or workpiece carriers are automatically indexed to and worked on in the heat sealing station.

We offer the complete concept, design construction and implementation of complex heat sealing systems.

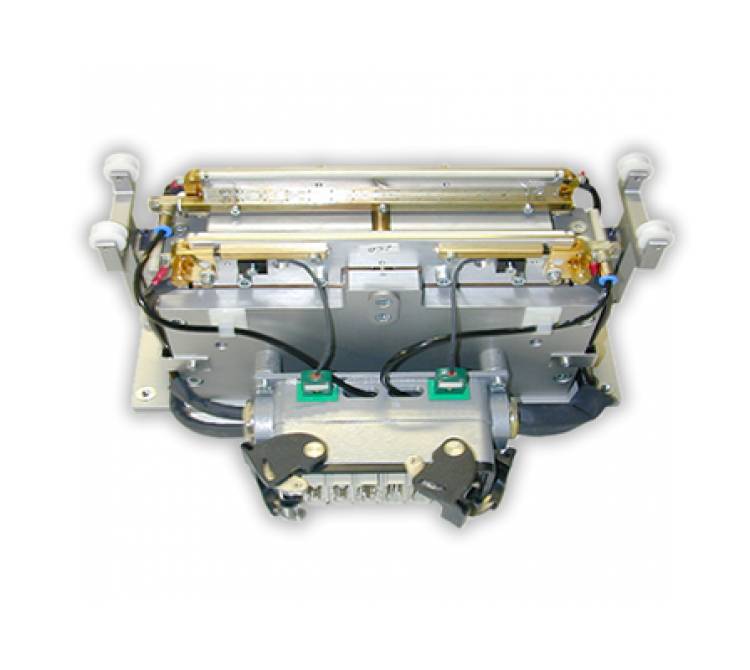

High accuracy temperature regulation to suit the pulse heating technique.

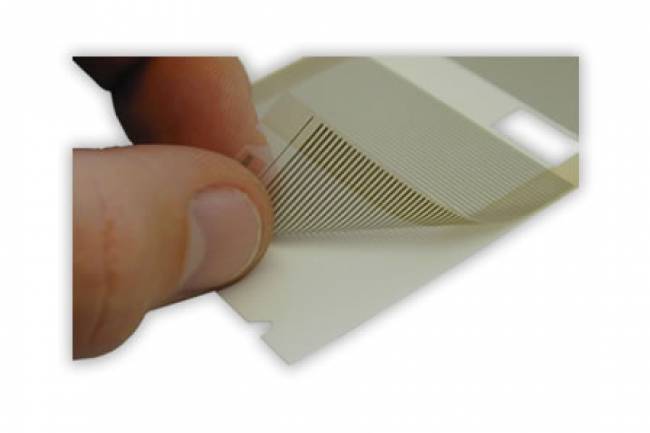

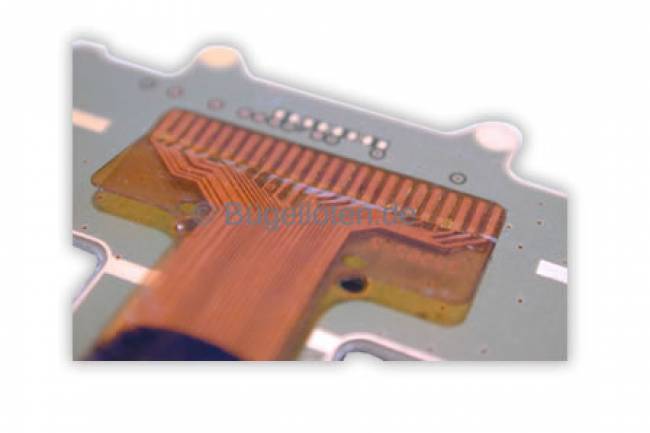

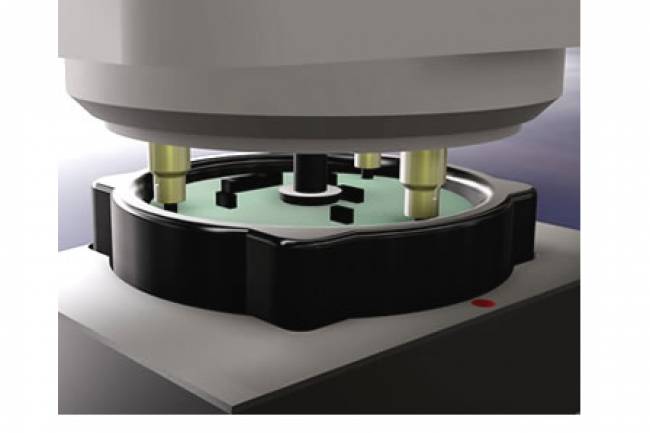

Heating rails from 5 to 300mm can be connected. Semi-gimballed mounting so that there is a uniform coplanar application of the heater rail onto the sealing face.

Triple temperature monitoring of the heater rails.

The heat sealing head has integrated force and path measurement.

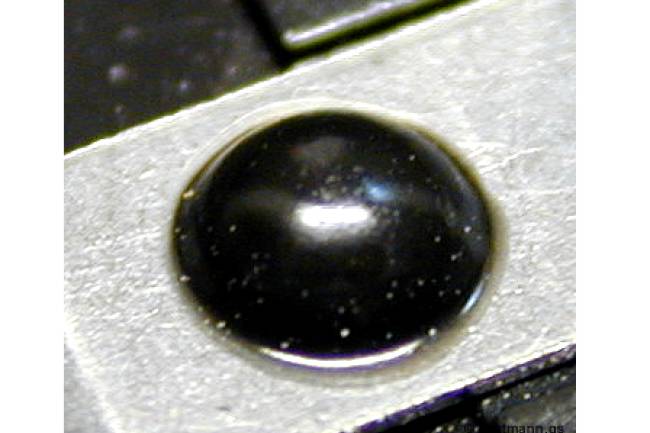

Manual and automatic silicon belt conveyor system for a thermally conductive silicon belt.

This belt protects the heater rail and the product from the transient very high forces which are necessary for the heat sealing process and improves product quality by better distribution of the adhesive, especially on the circuit board side.

Product specific component holders The system can be made to suit specific customer requirements