- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- OLED on PCB

- Example for Hot Bar Soldering application

- OLED on PCB

- Hot Bar Soldering application

- OLED on PCB

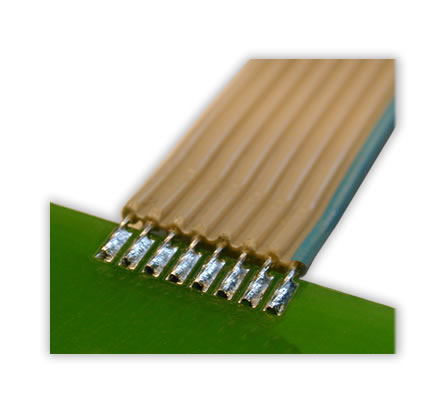

- Hot Bar Soldering application

- Ribbon cable on PCB

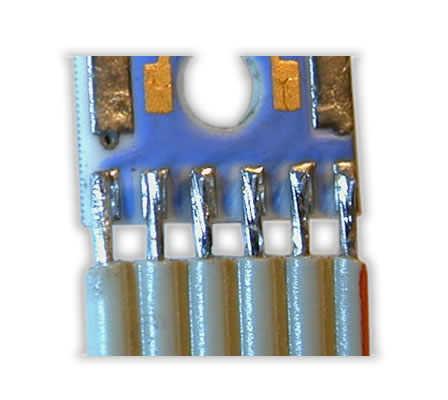

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Ribbon cable on PCB

- Hot Bar Soldering application

- LCD on PCB

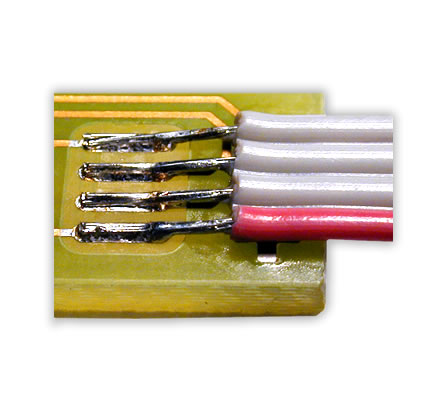

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Hot Bar Soldering application

- Flex foil on PCB

- Example for Hot Bar Soldering application

- Flex foil on PCB

- Example for Hot Bar Soldering application

- Stranded wires on metallic support

- Hot Bar Soldering application

- Stranded wires on metal foil

- Example for Hot Bar Soldering application

- OLED on PCB

- Example for Hot Bar Soldering application

- LCD on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on PCB

- Example for Hot Bar Soldering application

- Stranded wires on tissue structure

- Hot Bar Soldering application

- OLED on PCB

- Example for Hot Bar Soldering application

- Flex foil on PCB

- Example for Hot Bar Soldering application

- LCD on PCB

- Example for Hot Bar Soldering application

- Flex foil on PCB

- Example for Hot Bar Soldering application

- Flex foil on PCB

- Example for Hot Bar Soldering application

- Ribbon cable on PCB

- Example for Hot Bar Soldering application

- Ribbon cable on PCB