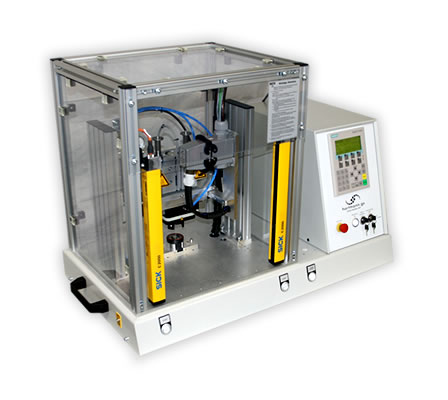

HVS20i

Heat staking system for use with a hand held thermode.

A temporarily heated system, where active cooling of the product takes place after the heating phase.

This system is intended for applications which allow manual feed of the heat staking die.

The operator feeds the heat staking die, which is fixed to a handle, to the product to be heat-sealed and he then starts the heat staking process by means of a separate starter switch or a foot switch.

The heating phase, programmed into the control system, is started and the product is formed under the manual forcing action of the operator.

Typically, the heating phase runs to 2-3 seconds.

After the heating phase, the die and the formed product are actively cooled at the programmed temperature. The die can finally be removed from the product.

The total heating process can be programmed as required in the control system and is monitored in correspondingly adjustable limits.

Warning â and malfunction messages relating to over- and under-temperatures are reported to the operating control panel.

Furthermore, the heating process is also monitored by an additional temperature sensor fitted to the die.

Interchange or replacement dies can be replaced very quickly via a plug connection and can be calibrated into the system in less than a minute by means of the automatic calibration function.

The forming die is tailor-made or adapted by us. And there are no limits to the shape.

Our innovative coating technologies ensure the maximum possible operating life of the heat staking die even with extremely compact plastics and provide maximum resistance to the abrasive wear and erosion to which the forming surfaces in contact with the product are exposed. Coatings with a micro hardness (HV 0.05) up to 3,300 are used.

Please be aware that not all applications are suitable for manually applied force during the staking process. Please contact us and we will gladly advise you in the selection of the most suitable system.